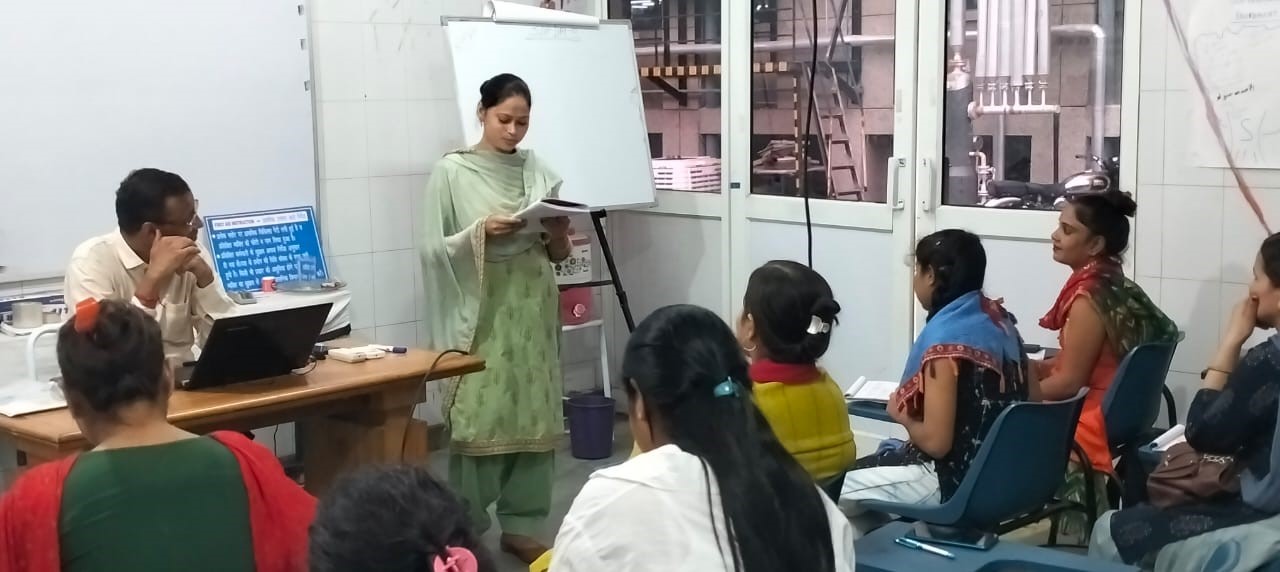

Following the Effective training of SDP and A-SDP to the Supervisors and assistant supervisors, the task is to implement and improve efficiency on the shop floor. The Supervisors and the Assistant Supervisor encountered several difficulties as they descended to the base to boost output. One of the most significant difficulties they faced came from the Operators

On the floor, implementation can be successful with the operator's assistance. The operators had to assist them in finishing the task. Therefore, a unique operator course Pro Skill (PASTA Workshop) was designed after knowing the difficulties in implementation. Then Methods discussed how to achieve the same training objective with the OGTC and Factory teams for the Operator's Training

Methods designed a three-hour-long intensive training course for the operators. The following areas are the course's main focus:

- What is Product, Process and Motion?

- PASTA – Special tool to improve the productivity

- Work Place Layout

- Needle Running time

- Right First time (RFT)

- 5S

- Absenteeism

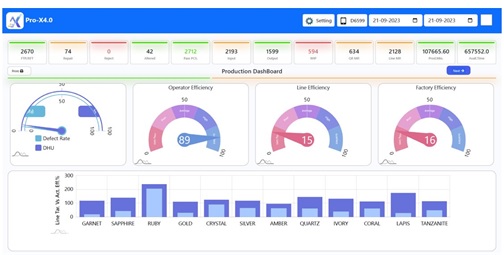

PASTA - One of the key instruments for unburdening the operators while standardization the process across the entire firm. Most people think it takes work to standardize in the garment industry because it's labor-intensive. For example, if one operator completes an operation at an efficiency of 80%, the other operator will not be able to do so. The standardization in the processes is the cause. To address this, the Methods created PASTA, a unique tool.

| Pick Up | Align | Sew | Trim | Aside |

| As Close as possible to needle | As Minimum as Possible | As Long as Possible | As Automatic as Possible | As Convenient as possible to the next operators |

| As Simultaneous as Possible | Eg – 30 Cm straight line without Stop | Suction Cutter | Use Work aid for Automatic disposal | |

| Fixed Blade for Overlock | Dispose by Sliding. | |||

| Cut Thread with Trimmer in hand |

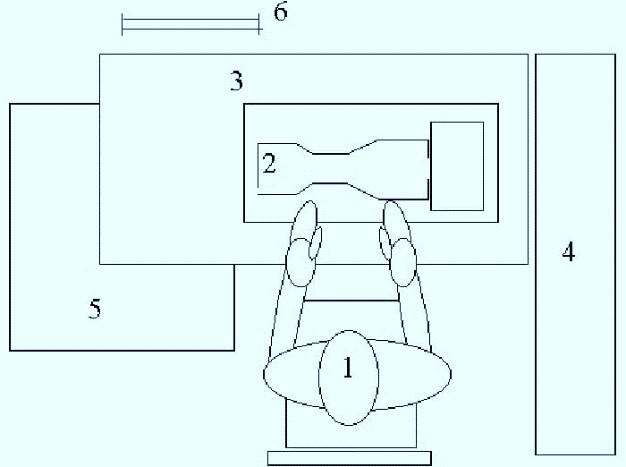

Workplace Layout:

Having a suitable workplace layout is vital. Most often, handling gets worse because of improper workplace design. Methods taught them how to arrange and dispose of the parts through this module to reduce their time.

Needle Running Time: The Only time we make money is when the needle moves.

Through this module, Methods taught them how to increase the needle running time. Methods made them understand that if the operators were late for 5 mins, what would the effect on the day be? After this operator understands the value of every minute.

5S -

In this module, they learned how to do basis 5s on their workstations. Sample images were shown to them.

Absenteeism

The critical place where all the factories suffer is Absenteeism, and in most cases, unavoidable. So Methods taught them the different types of Absenteeism and ways to take leave in case of need; through this, the operators understand the importance of informing the leave in advance.