Pro X 4.0

Pro X 4.0 is a result of over 4 decades of experience in the apparel manufacturing industry, with a commitment to transform the apparel factories into SMART and SUSTAINABLE factories . After executing more than 500 projects in the sector, we understood the solutions which could eliminate the bottlenecks of the factory.

During the course of time, we understood that the main challenges that the industry faces even today, primarily related to data and technology are-

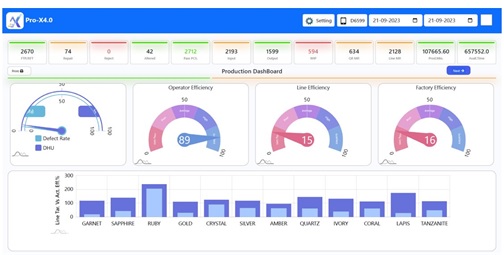

1. Lack of Real Time Tracking & Monitoring - Data as we know is the key in the modern world. The absence of real-time data. has halted the growth and development of numerous factories and the sector in general. With real time tracking, we believe that the factories can unleash a force which can transform the factory in every aspect. Real time monitoring of the factory efficiency, group & individual efficiency among other data sources can open up an ocean of opportunities for the factory to understand, act and transform.

2. Deprioritised Data Analysis & Redressal - Lack of data eliminates the opportunity to study the data in detail and understand the bottlenecks in order to arrive at a solution. Factories which have access to Real Time Monitoring understand the benefits of proper data analysis, which has short and long term benefits. The operation or the manpower which is leading to a possible delay or degradation in quality can easily be identified through data analysis. Just imagine if the identification is done in real time, the amount of time, energy and resource (fabric & manpower) the factory would be able to save!

3. Segregated Monitoring Of Various Departments & Not So Easy Access To Dashboards - Monitoring of various departments of the factory, including the Sampling, Cutting, Production Floor, Quality, Maintenance in one single app can ease up a lot of work, especially when it concerns the Management. An Application on the phone or your tablet, which could in real time update the Management about the current status and statistics of the factory could increase accountability among the various stakeholders involved.

4. Digitisation - Among the above mentioned points, digitisation has seen a comparatively sharper upward trend. Factories have believed in the power of digitisation and hence have executed it at most places. Digitisation helps in proper tracking, monitoring and analysis, which further opens up opportunities to optimise the process or the operation.

Having witnessed these challenges, we developed an application - Pro X 4.0, which is a one stop solution for all your apparel factory needs. The application can be accessed through Laptop, Tablet, Phone which makes it easier for you to track your factory in real time.

Pro X 4.0 has a dedicated module for Sampling, Cutting, Production, Quality, Maintenance and more, which tracks the factory from cut to pack for you. Methods of apparel manufacturing industry, real time bottlenecks, efficiency of the factory, lines and that of individual operators can be tracked, which makes DECISION MAKING much easier. Pro X 4.0 has been key in meeting the Environmental Social & Governance goals of the factory.

The application further creates a sense of accountability among the workforce and also promotes healthy competition, which is key to improving the efficiency, productivity, profitability and the growth of the organisation.

Let’s discuss this further?? Click here