Introduction

The process of sampling carries huge significance in the sewn product industry, as it determines the approval of future orders from buyers and hence influences the business of the manufacturing units directly.

Further, sampling is a critical component of pre-production processes within the garment industry. Manufacturers produce prior samples of styles to obtain approval and kickstart the production of garments before creating bulk orders.

Manufacturers develop various types of samples based on the requirements of their respective buyers. Many departments & individuals are involved directly and indirectly in the sampling process, including designers, buyers, sourcing, production teams, quality team, and the costing department at various levels. Hence, it is of prime importance for the factory to manage its Sampling with due diligence

Challenges In Sampling:

Like any other industry and department, sampling has its own challenges. Some of the common challenges of the sampling department are:

- Delays : Not so efficient workflow, poor communication, and lack of tracking are some of the reasons why traditional sampling procedures frequently experience delays.

- Cost Overruns: During the sample-making stage, cost overruns are caused by inaccurate time estimates, redundant procedures, and a lack of real-time monitoring.

- Quality Issue: In the absence of a defined and overseen procedure, maintaining consistent quality across samples becomes a challenging task.

- Sampling Room Performance: The samples & their quality is of prime importance to the manufacturing unit, hence ample time is given for the sample creation. Despite that, it has been observed that the sampling room productivity is comparatively lower than the production floor productivity, by a fairly large margin. Lack of process optimisation and monitoring in the sampling department are one of the main reasons for the poor performance of the sampling room.

- Lack of Transparency: It becomes difficult for the merchant to keep track of the sample progress and spot production cycle obstacles, leaving scope for potential delays.

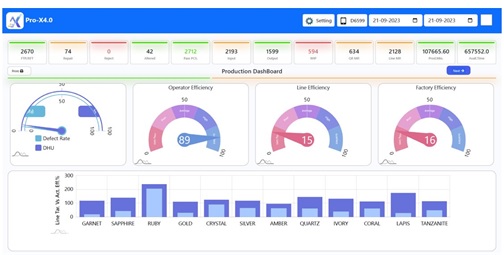

Pro X 4.0 Sampling Module: Increasing Transparency In Sampling

The Pro X 4.0 Sampling Module turns out to be a revolutionary tool for the garment manufacturing industry. It presents a thorough resolution to the challenges encountered throughout the sampling process, by bringing in transparency and accountability.

- Selecting a Master Process: Manufacturers can select a master process, such as cutting , sewing, packing, embroidery, and more, using the Pro X 4.0 Sampling Module. An alert is sent at the start and at the ending of each process

- Real-timing Monitoring and Alerts: This module lets employees determine the lead time for every stage of the procedure. Workers scan the QR code, and the module notifies the specified merchant as soon as any step is started, or completed. Hence, the merchant & the sampling incharge are in sync with the live status of the sample. Transparency is ensured, and delays are quickly identified and addressed, thanks to this real-time monitoring..

- Progress Tracking and Efficiency Analysis: The module gathers information about the typical time needed for each task, allowing the sampling incharge and the management to assess the productivity of their workforce and the quality of their output. By facilitating the sample in-charges to track the development of various samples at different stages, the data improves overall visibility and control and further keeps in sync with the deadline and the live status.

- Cost Control and Productivity Gains Manufacturers may precisely measure the expenses associated with producing samples by keeping track of the man-hours spent on each sample. Making educated decisions about resource allocation and process optimization is made possible by this data, which enables a thorough examination of the sample room's productivity, further giving a deep insight into the manufacturing cost of that particular style.

- Quality Control and Approval Monitoring: The quality sheet in the Sampling module makes it easier to keep track of the quality aspects of the sample. The quality sheet focuses on the specifications, workmanship, fit, measurement, among others parameters of the sample. The data makes it easier to predict the percentage of First Time Right (FTR) samples, both from the Sample Incharge’s and the Buyers end. This information is crucial for streamlining design processes, cutting down on bottlenecks, and further guaranteeing higher levels of quality in the finished product.

- Effective Communication and Escalation: The application is further equipped with an Escalation feature, in which if there is any delay at any stage of the sample development (let's say there has been no update, after the fabric for the sample was cut the last day), an escalation will be sent to the merchant automatically, mentioning the escalation. This removes the possibility of potential delays and further encourages effective teamwork, communication & accountability, which enhances the overall productivity of the sampling room.

- Sampling Room Performance Monitoring : The Sampling feature of Pro X 4.0 thus monitors the sampling productivity and efficiency of the sampling room. The data provided by the application acts as a great source to analyze and further find ways to optimize the processes and thus the performance of the sampling room. The data further gives a valuable insight, heading to the production of that particular style.

- Fair Wage Practices: The efficiency tracking feature of the Pro X 4.0 sampling module also includes worker productivity monitoring, thus increasing transparency and furthering the scope of evaluation based on the individual performance of the worker/resource.

The Pro X 4.0 Sampling Module's ESG Compliance:

In today's socially conscious world, compliance with ESG (Environmental, Social, and Governance) standards is essential. The Pro X 4.0 Sampling Module supports the following in line with ESG principles:

- Environmental Sustainability: The module helps save resources, time and potential waste in the manufacturing cycle by eliminating needless delays, streamlining procedures thus enhancing overall productivity & efficiency of the sampling room, and getting more First Time Rights.

- Social Responsibility: Within the manufacturing ecosystem, social equality is promoted via effective worker productivity monitoring and increasing scope for evaluation based on individual performance.

- Governance and Transparency: By providing adherence to moral business conduct and governance principles, the module's real-time tracking and monitoring tools improve transparency in the sampling process.

In summary :

When it comes to tackling the challenges & bottlenecks encountered by the garment manufacturing sector during the sampling process, the Pro X 4.0 Sampling Module is a huge advancement. This creative solution's cutting-edge features support social responsibility, good governance, and environmental sustainability in addition to streamlining operations and making it more efficient, productive & transparent. It is imperative for the sewn product industry to adopt technological innovations such as the Pro-X4.0 in order to remain ahead of the curve and secure a more sustainable and efficient future.