By Din Bandhu, Business Head – Methods Apparel Consultancy, India

In an era where fashion is not only about aesthetics but also about agility, efficiency, and ethical production, the human element inside factories has never been more critical. Amid growing global competition and tighter margins, one thing is becoming increasingly clear: empowering the workforce through well-designed incentive structures is no longer an option—it’s a necessity.

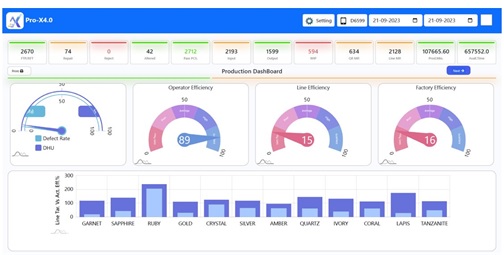

Pro-X4.0 Mobile Application.

At Methods Apparel Consultancy, we have seen first-hand how a factory’s transformation begins with investing in its people. But this investment needs to be strategic. Once a factory establishes the right infrastructure to measure, manage, and maximise worker performance, it opens doors to a variety of forward-looking policies. Among these, a Performance-Linked Incentive (PLI) system stands out as a game-changer—especially when enabled by the right digital tools like Methods’ Pro-X4.0 Mobile Application.

The Power of Incentives: More Than Just Bonuses

Incentives are not merely financial perks—they’re psychological drivers. A thoughtfully structured incentive system not only compensates for time but also rewards dedication, discipline, and excellence. When linked to real-time efficiency metrics, bonuses become a powerful motivator for consistent performance.

To create immediate impact and build trust, we strongly advocate for weekly or fortnightly disbursement of incentives. Unlike traditional annual or quarterly bonuses that feel distant and impersonal, this system creates instant gratification and sustained motivation , reinforcing the message that hard work is recognised and rewarded now.

Group & Individual Rewards: A Balanced Formula

A successful factory ecosystem balances teamwork and individual brilliance . That’s why our recommended incentive model includes both group-level bonuses and individual recognitions . Group targets nurture accountability and camaraderie, while individual rewards ensure that top performers are duly acknowledged.

Crucially, the bonus structure should be graded and benchmarked to the factory’s average efficiency. Targets must be ambitious yet achievable, encouraging every worker to raise the bar while keeping the system transparent and fair.

Integrating Quality and Attendance

True operational excellence is not just about speed—it’s about getting it right the first time . That’s why we advocate integrating quality metrics, like Defects per Hundred Units (DHU), into the incentive system. Workers maintaining less than 2% DHU, for instance, can be rewarded to encourage a culture of precision and pride in workmanship.

Attendance , too, plays a key role in maintaining line stability. Workers with consistent attendance records contribute to smoother production runs—and should be recognised as such.

Innovation Spotlight: The ‘Jump Start Bonus’

One of our most successful incentive experiments was in Sri Lanka, where a factory struggling with a 55% average efficiency adopted our ‘Jump Start Bonus’ model. The promise was simple: workers achieving 60% efficiency would receive a special bonus. Within two months, 80% of the workforce surpassed the target—a testament to how achievable goals, coupled with instant recognition, can drive behavioural change and boost morale.

Beyond Operators: A Culture of Inclusion

Incentives should not be limited to operators alone. At Methods, we champion a holistic approach, where supervisors, industrial engineers, mechanics, and production executives also share in the success. Each role has a set of measurable KPIs—from WIP and absenteeism rates for supervisors to machine downtime and response times for mechanics.

This inclusive incentive system strengthens teamwork, builds interdepartmental trust, and reinforces a shared commitment to excellence.

Digital Enablement: The Role of Pro-X4.0 Mobile Application

None of this is possible without the ability to track performance at a granular level—and that’s where our Pro-X4.0 Mobile Application becomes indispensable.

Designed specifically for garment factories, Pro-X4.0 enables real-time tracking of:

- Individual and group efficiency

- Operation-wise quality metrics

- Attendance and absenteeism

- Machine downtime and maintenance efficiency

- Standard vs actual time for tasks